Specifications

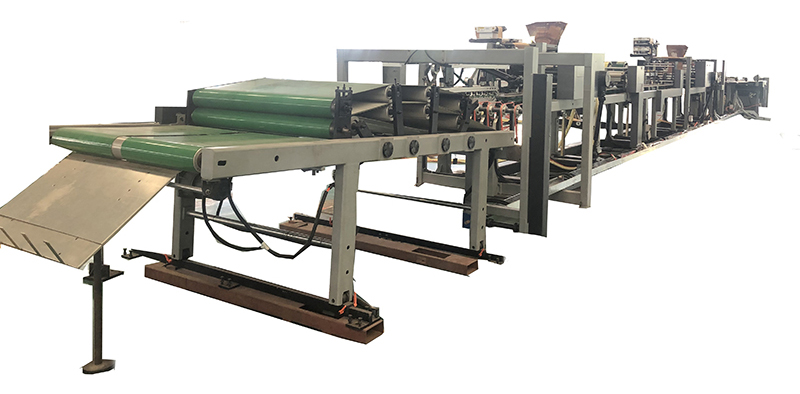

| Size | 28.7×5.2×4.3m |

| Weight | 19.1 t |

| Bag length | 365-850mm |

| Bag width | 250-600mm |

| Bag bottom width | 100-200mm |

| Productivity | ≤60 sacks/min |

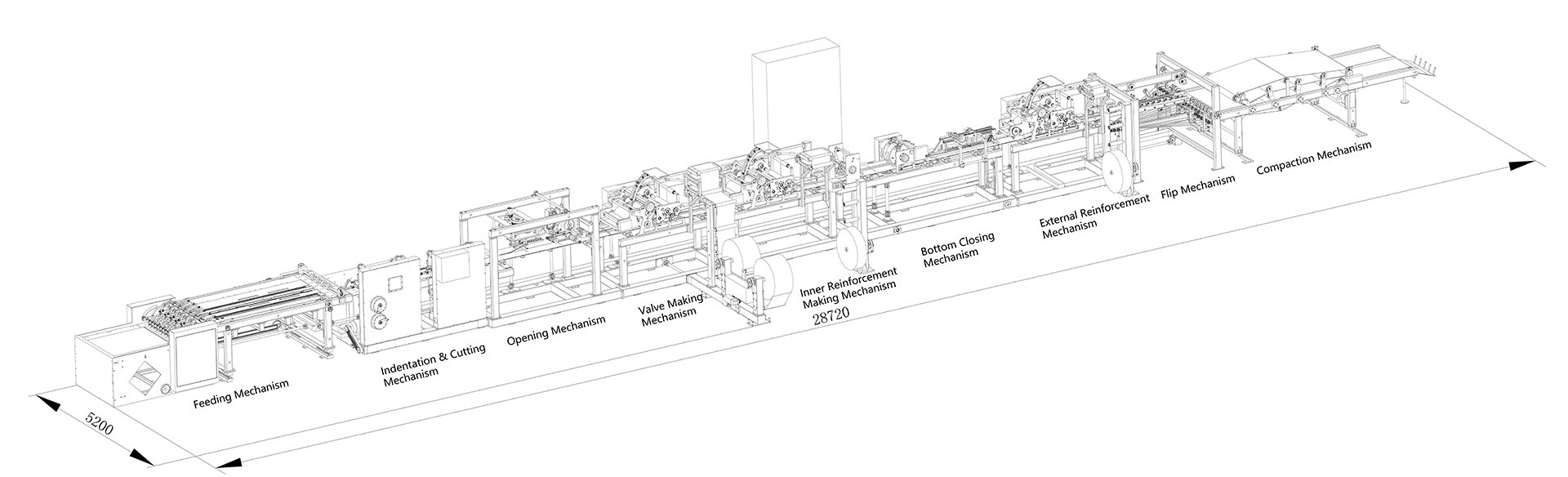

Configuration included

- Feeding unit

- Flush cut unit

- Vacuum opening & bottom forming unit

- Valve making unit

- Bottom forming unit

- Flipping unit

- Compacting & valve bag discharging unit

Optional Configurations

- Interior reinforcement mechanism

- Exterior reinforcement mechanism

FM2018 valve sack bottomer (one end pasted) overview

Details

-

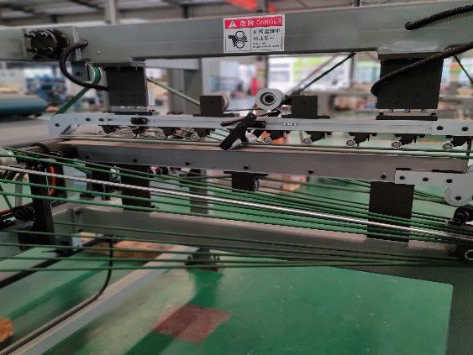

Feeding unit

The feeding mechanism of valve sack bottomer employs rotary rollers to feed. Small rollers rotate around big rollers. Meawhile, small ones rotate reversely to take the feeding. A big roller rotates for one time is capable of feeding 8 paper bag tubes.

Rotating vaccum feeding is the easiest, most convenient way, also considered as reliable and stable. Equipped with arranging and positioning device, this unit ensures the positioning precision of paper bag tubes.

-

Flush cut unit

The flush cut unit is capable of making indentations without stopping the machine or adjusting the speed.

This mechanism of valve sack bottomer is equipped with flush cut, mainly used for the bottoming of straight-cut end paper bag tubes. The unit cuts two times on both ends of paper sacks.

-

Vacuum opening & bottom forming

The vacuum opening of valve sack bottomer opens the paper bag tube, enabling the handling unit to get inside the tube. The handling unit can open the paper bag from top to bottom.

This mechanism flattens the bags, assisting the handling unit to shape the bag bottom. Meanwhile, the block bottom of paper bag is compacted by the flattening device.

-

Valve making

The valve making mechanism pastes valve paper on the bags, forming a valve.

Customers can adjust the parameters on the screen and set valve paper length.

-

Interior reinforcement mechanism

The interior reinforcement mechanism pastes reinforcing strip inside the valve to increase its strength.

-

Bottom forming unit

The bottom forming unit is equipped with bottom indentation device to assisting bottom forming, supported with glue wheel device whose shape is adjustable according to the needs and specifications of paper bags. Remember to stick the glue plate to its set place afterwards.

The forming unit is comprised of supporting panels, among which the inward panels support the bottom paper. Outwards panels function as a guide for the bottom paper to form into rectangular-shaped bottoms. Then the compactor will make the bottoms more durable.

The panel size can be adjusted according to the production needs of different bottom size.

-

Exterior reinforcement mechanism

The exterior reinforcement mechanism pastes the reinforcing strip outside the valve to enhance the valve strength.

-

Flipping unit

After bottoming, paper sacks are changed from verticality to horizontality by the flipping unit.

-

Compacting & valve bag discharging unit

Through the flipping mechanism, paper sacks are sent in at a lower speed while passing the compacting belt. The compacting effect will be more obvious after the bags are arranged together. The mechanism is equipped with counting device; customers can preset paper bag number in the system.

The compacting and counting unit of valve sack bottomer is equipped with vacuum absorbing and accelerating separating device, which is used to separate piled-up paper bags when the bags have reached certain amount set by the system.

-

S-shape compacting unit

The S-shape compacting unit is used to compact bottomed paper sacks, bringing sacks into S-shape. With enough compacting time and high adhesive paper bag bottoms, sacks produced by our valve sack bottomer are tidy, of good quality in compacting and indentation, suitable for large scale paper bag production.

This device can be used only with valve sack bottomers (both end pasted) as a set.

As an experienced manufacturer of paper sack making machines since 1983, Youniker has demonstrated its expertise and professionalism in numerous projects across many fields requiring industrial paper bag production. Apart from individual equipment for paper bag making such as bag tube forming machine and bag bottom pasting machine, we can also supply complete paper bag manufacturing line consisting of paper industrial sack tuber and paper bag bottomer machines. Whether you are looking for cement sack making machine, paper animal feed bag making machine, or other paper sack production equipment for powder or granular goods, we will be your reliable source of industrial paper bag machines.