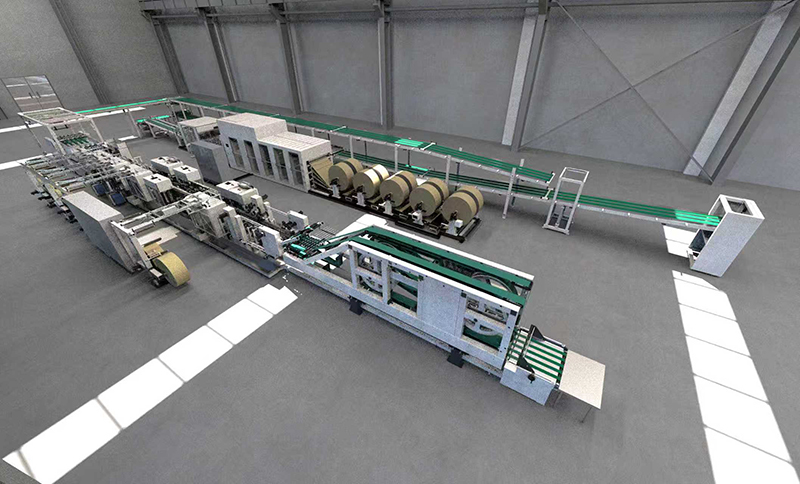

Fully Automatic Integrated Inline Paper Valve Bag Production

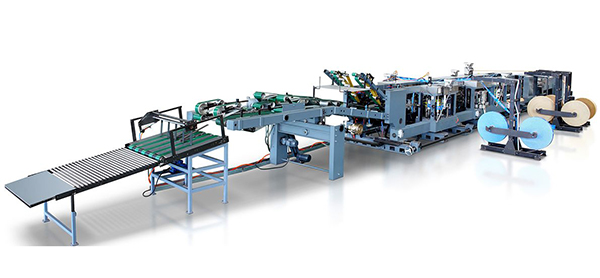

This fully automatic inline paper valve bag production line integrates printing, tube forming, and bottom pasting into one continuous system, enabling full production from raw material to finished bags. The line is designed with a modular structure, so different functions can be configured according to each customer’s requirements. It provides efficient and environmentally friendly packaging solutions for cement, chemicals, building materials, food, and other powdered or granular products.

| Tube length | 500-1100 mm |

| Bag length (both ends pasted) | 330-920 mm |

| Bag width | 330-600mm |

| Bottom width | 90-200mm |

| Bag center distance | 240-800mm |

| Maximum productivity | 230 bags/min |

| Size (high-configuration version) (L×W) | 45×18 m |

| Power (high-configuration version) | 234 kW |

- Fully automated workflow from roll printing, tube forming, and bottom pasting to finished bag collection

- Higher production efficiency compared with traditional separated equipment, with labor demand significantly reduced

- Centralized intelligent control using PLC and HMI, allowing one-touch operation and fast parameter switching

- Servo-driven register control ensures register accuracy up to ±0.1 mm, delivering clear and attractive printing quality

- Supports 4 to 8 color printing units to meet different branding and customization needs

- Automatic bottom pasting system with accurate gluing position and strong bonding strength to ensure a stable bag bottom

- Precision valve forming technology ensures smooth filling performance and excellent sealing

- Key components are sourced from internationally recognized brands for reliability, durability, and easier maintenance

- Modular design allows future upgrades and production expansion when required

- Touchscreen interface for easy operation and quick product size changeover

- Centralized monitoring enables one operator to oversee the entire production line

As an experienced manufacturer of paper sack making machines since 1983, Youniker has demonstrated its expertise and professionalism in numerous projects across many fields requiring industrial paper bag production. Apart from individual equipment for paper bag making such as bag tube forming machine and bag bottom pasting machine, we can also supply complete paper bag manufacturing line consisting of paper industrial sack tuber and paper bag bottomer machines. Whether you are looking for cement sack making machine, paper animal feed bag making machine, or other paper sack production equipment for powder or granular goods, we will be your reliable source of industrial paper bag machines.