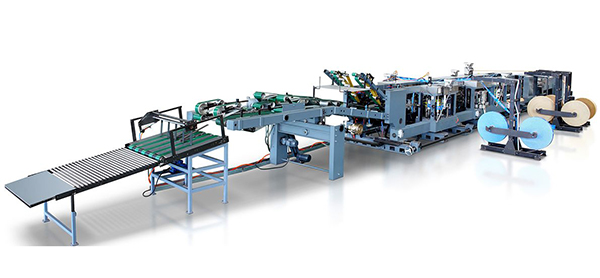

Paper Animal Feed Bag Production Line

This valve sack production line is comprised of Youniker ZT1962S valve sack tuber and FM2018 one-end valve sack bottomer, applicable to the production of large size valve sacks used to fill foods and animal feeds.

Specifications| Size | 31×4×3.5 m |

| Weight | 32 t |

| Types of cutting | flush-cut + stepped-end cut |

| Tube length (stepped-end cut) | 500-1100mm |

| Tube length (flush-cut) | 500-1100 mm |

| A-shape tube width | 370-620 mm |

| M-shape tube bottom width | ≤80 mm |

| Cuttable | 2-4 layers of paper+1layer of film |

| Maximum productivity | 175 sacks/min |

| Maximum roll paper diameter | 1300 mm |

| Size | 28.7×5.2×4.3m |

| Weight | 19.1 t |

| Bag length | 365-850mm |

| Bag width | 250-600mm |

| Bag bottom width | 100-200mm |

| Productivity | ≤60 sacks/min |

- Capable of producing large size valve bags at a high speed, loading weight of valve sack surpasses 25kg;

- Equipped with reinforcing strip, suitable for high pressure filling;

- Higher productivity generates lower production costs for customers;

-

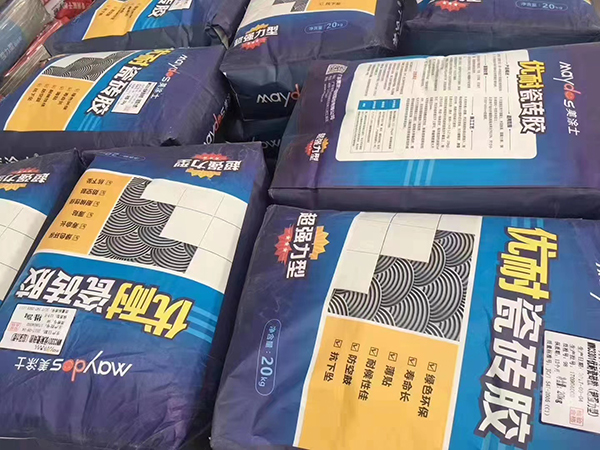

Kraft valve sack

Kraft valve sacks are suitable for large particulate substances such as cement, corns and coffee beans. This kind of valve sack has no seal, therefore it is lower in cost.

-

Film laminated paper valve bag

Film laminated paper valve bags has a film facing inside the valve, therefore the film will stick to the top of the bag to achieve sealing effect after filled out. Film laminated bags outstrip the kraft valve bags with better sealing effect, suitable for powdered substances.

-

Hot-melt glue sealing paper valve bag

Hot-melt glue sealing paper valve bags has paper strip facing upward, which is lined a hot-melt film. The valve will be sealed after the bag is filled out, achieving good sealing effect, suitable for powdered substances.

-

Ultrasonic sealing paper valve bag

The paper valve bag has an extended sleeve with hot-melt film lined, which will melt to achieve sealing by using ultrasonic sealer after filling. Ultrasonic sealing paper valve bag is brilliant in sealing, suitable for powdered substances.

-

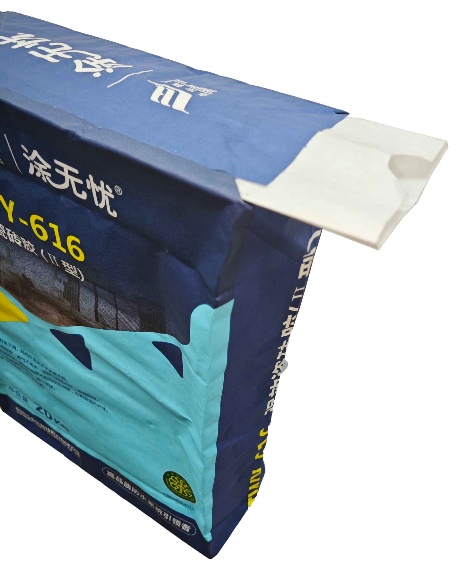

Kraft paper valve bag with thumb notch

Kraft paper valve bag with thumb notch has a semicircular notch on the valve, convenient for the workers to open the valve with thumbs while filling materials. The rest part of this paper bag is identical to kraft valve sacks.

Note: This valve sack production line features FM2018 one-end valve sack bottomer, suitable only for the production of large size valve sacks. If you need to produce valve bags used to preserve mortar, pigment, chemicals and other powdered substance, please visit the link for dry mortar bag production line; If bags for cement, activate carbon and other particulate substance is needed, please visit the link for cement bag production line.

As an experienced manufacturer of paper sack making machines since 1983, Youniker has demonstrated its expertise and professionalism in numerous projects across many fields requiring industrial paper bag production. Apart from individual equipment for paper bag making such as bag tube forming machine and bag bottom pasting machine, we can also supply complete paper bag manufacturing line consisting of paper industrial sack tuber and paper bag bottomer machines. Whether you are looking for cement sack making machine, paper animal feed bag making machine, or other paper sack production equipment for powder or granular goods, we will be your reliable source of industrial paper bag machines.