The design department draws a BOM list of materials needed for production based on customers’ needs, the production department is responsible for drafting production plan. Meanwhile, the procurement department acts according to BOM list and their procurement plan made for components. If pieces need processing, paper should be printed and stamped by office, and then the paper will be sent to suppliers or be made by our plant. For pieces of market standard, we procure them directly.

After suppliers sent the components to the warehouse and finished required paper work, the inspection department verifies the pieces. If the pieces meet the standard, then they will be put in storage. If not, then return them. The production department claims the components needed then assemble, in which important pieces need to be inspected before installation.

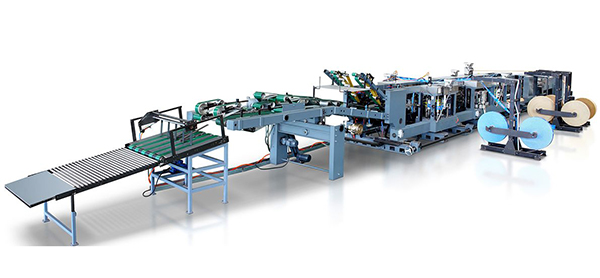

Processing machineryLathe, milling machine, grinding machine, sawing machine, rocker arm drilling machine

Inspection equipment includes hardness inspector, chromium coating test equipment, inspection platform, caliper, microcalliper, dial indicator, height gauge and try square.

-

Height gauge is used to measure the size of components precisely.

-

Rockwell hardness tester is applied to see if the components reach the hardness standard.